Phenol-Formaldehyde Resin (PR) is a type of thermosetting plastic that has been used in various industrial applications for many years. With excellent mechanical, electrical, and thermal properties, PR has become a popular choice in automotive, construction, and electronics industries. However, the manufacturing process for PR involves using formaldehyde, which can negatively impact human health and the environment. Furthermore, the limited recyclability of PR has led to concerns about its impact on waste management and sustainability.

PR was first developed in the early 20th century and became commercially available in the 1920s. It was initially used in electrical insulation but expanded to other industries, such as construction, automotive, and consumer goods.

Definition:

Phenol-Formaldehyde Resin (PR) is a thermosetting polymer made by the reaction between phenol and formaldehyde. The reaction forms a network of covalent bonds that create a three-dimensional structure, resulting in a rigid and durable material. PR is a type of phenolic resin, which is a generic term for any thermosetting plastic made from phenol and formaldehyde.

Material Properties:

PR is known for its exceptional mechanical, electrical, and thermal properties. It has high tensile strength, impact resistance, and dimensional stability. It is also a good insulator, making it ideal for electrical applications. PR can withstand high temperatures, making it suitable for use in high-temperature environments.

Industrial Usage:

PR is used in a wide range of industries, including electrical, construction, automotive, and consumer goods. In the electrical industry, PR is used as an insulating material in transformers, motors, and electrical switchgear. In the construction industry, it is used as a binding agent in the manufacture of particleboard, plywood, and other composite materials. In the automotive industry, PR is used in the manufacture of brake pads, clutch facings, and other friction materials. In the consumer goods industry, it is used in the manufacture of kitchenware, tableware, and other household items.

Application Areas:

PR is used in various applications due to its excellent material properties. Its application areas include:

- Electrical Insulation: PR is used in the manufacture of electrical insulation materials, such as laminates, circuit boards, and transformers.

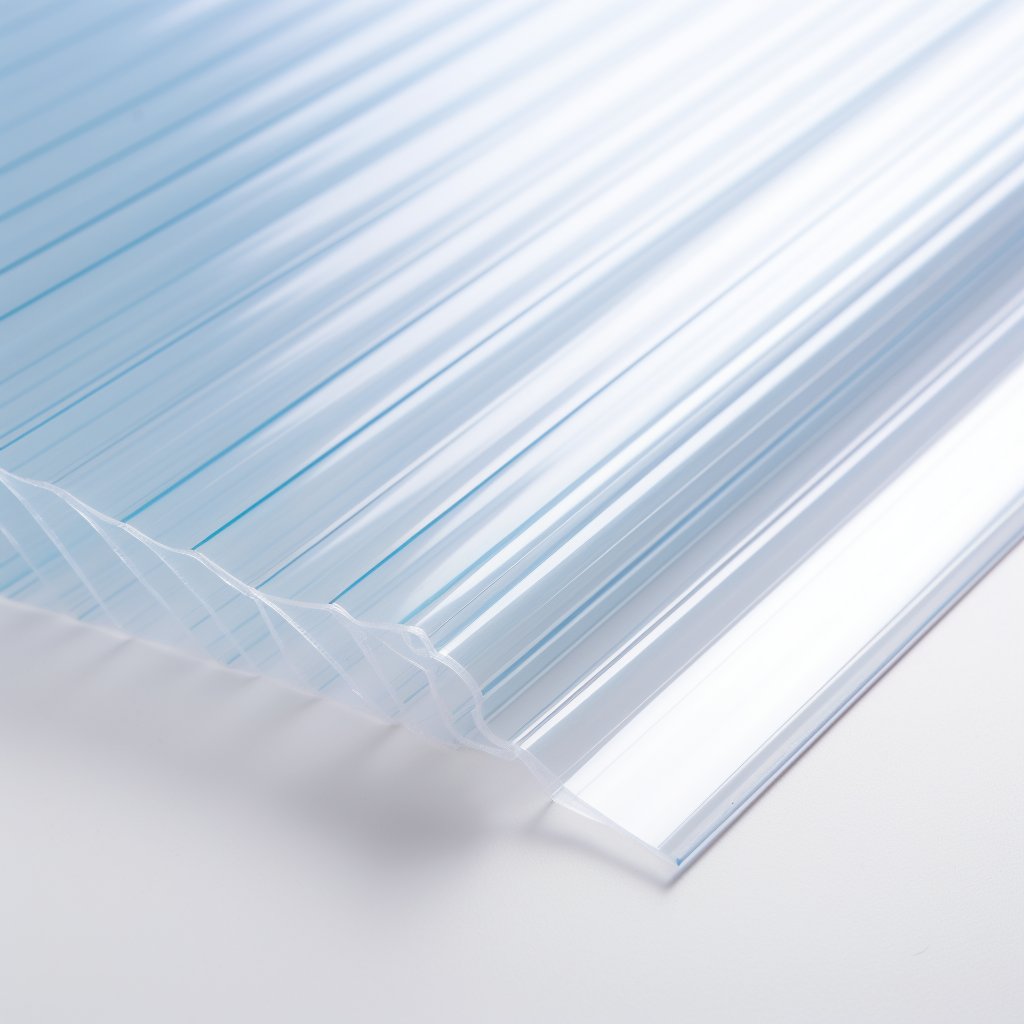

- Construction Materials: PR is used as a binding agent in the manufacture of particleboard, plywood, and other composite materials.

- Automotive Friction Materials: PR is used in the manufacture of brake pads, clutch facings, and other friction materials.

- Consumer Goods: PR is used in the manufacture of kitchenware, tableware, and other household items.

Consumer Product Examples:

PR is used in various consumer products due to its durability and heat resistance. Some examples of consumer products made from PR include:

- Bakelite Jewellery: Bakelite is a type of PR used to manufacture jewellery in the 1930s and 1940s.

- Kitchenware and Tableware: PR is used in the manufacture of kitchenware and tableware, such as plates, bowls, and cups.

- Electrical Appliances: PR is used in the manufacture of electrical appliances, such as toasters, coffee makers, and irons.

Recycling:

PR is a thermosetting plastic, which means it cannot be melted and reformed like thermoplastics. This limits its recyclability, and it is often disposed of through incineration or landfill. However, some companies are developing technologies to recycle PR, such as pyrolysis, which breaks down the material into its constituent parts for reuse.

Recycling PR can be challenging due to its thermosetting nature, but several methods have been developed to recycle the material. One method is pyrolysis, which involves heating the material in the absence of oxygen to break it down into its constituent parts. The resulting products can be used as fuels or feedstock to produce new materials.

Advantages of Recycling PR:

- Environmental Benefits: Recycling PR reduces the amount of waste sent to landfills or incinerators, which can reduce greenhouse gas emissions and conserve natural resources.

- Energy Savings: Recycling PR requires less energy than producing new PR from virgin materials, which can reduce greenhouse gas emissions and save on energy costs.

- Economic Benefits: Recycling PR can create new jobs and economic opportunities in the recycling industry.

Disadvantages of Recycling PR:

- Limited Recycling Options: The thermosetting nature of PR limits its recycling options, which can make it challenging to recycle and repurpose the material.

- Cost: Recycling PR can be more expensive than producing new PR from virgin materials due to the limited recycling options and processing requirements.

Environmental and Global Impact:

The disposal of PR can have a negative impact on the environment and global health. Formaldehyde emissions during the manufacturing process can contribute to air pollution, and improper disposal can lead to contamination of soil and water resources. Recycling PR can help reduce these impacts by diverting waste from landfills and reducing the need for new virgin materials. Additionally, the development of new recycling technologies and sustainable production methods can help reduce the environmental impact of PR and the plastics industry as a whole.

Advantages & Disadvantages

Advantages:

- Mechanical Properties: PR has excellent mechanical properties, such as high tensile strength, impact resistance, and dimensional stability. It is also resistant to wear and tear, making it ideal for use in high-stress applications.

- Electrical Properties: PR is an excellent insulator and can withstand high voltages, making it ideal for use in electrical applications.

- Thermal Properties: PR can withstand high temperatures without degrading, making it suitable for use in high-temperature environments.

- Durability: PR is a durable material that can withstand harsh environments and is resistant to moisture, chemicals, and UV radiation.

Disadvantages:

- Formaldehyde Emissions: The manufacturing process for PR involves using formaldehyde, which can harm human health if not properly controlled. Formaldehyde emissions can be reduced through proper handling and processing.

- Brittleness: PR can become brittle over time, especially when exposed to UV radiation, which can cause it to crack or break.

- Limited Recyclability: PR is a thermosetting plastic, which means it cannot be melted and reformed like thermoplastics. This limits its recyclability, and it is often disposed of through incineration or landfill.

- Cost: PR is more expensive than some alternative plastics, such as polyethene and polypropylene.

Comparison to Alternative Plastics:

PR has better mechanical, electrical, and thermal properties than alternative plastics, such as polyethene and polypropylene. However, it is more expensive and less recyclable than these materials. In some applications, such as consumer goods, alternatives like polyethene and polypropylene are preferred due to their lower cost and recyclability.

Market Price Developments:

The market price of PR is influenced by several factors, such as supply and demand, raw material costs, and manufacturing costs. The COVID-19 pandemic significantly impacted the PR market, with disruptions in the supply chain and decreased demand from certain industries. However, the market is expected to recover as economies reopen and demand for PR increases.

Future Market Prognosis:

The future of the PR market depends on several factors, such as innovation in recycling technologies, demand from various industries, and regulatory changes. The increasing focus on sustainability and reducing environmental impact is driving demand for alternative materials and recycling technologies, which could impact the PR market. However, PR’s unique properties and established use in various industries make it likely to remain an important material in the plastics industry for the foreseeable future.

Phenol-Formaldehyde Resin (PR):

Phenol-Formaldehyde Resin (PR) is a widely used thermosetting plastic that has excellent mechanical, electrical, and thermal properties. Its use has expanded to various industries, including electrical, construction, automotive, and consumer goods. PR is used in the manufacture of electrical insulation materials, construction materials, automotive friction materials, and consumer goods, such as kitchenware and tableware. Its durability and heat resistance make it an ideal material for use in consumer products.

It is important for the industry to continue to explore sustainable production methods and recycling options for PR to minimise its environmental impact.